nanofabrication of armor Nature's bottom-up .

Seashells are natural armor materials. The necessity for toughness arises because aquatic organisms are subject to fluctuating forces & impacts in the work of motion or through interaction with a moving surroundings. Nacre (mother-of-pearl), the pearly internal layer of plenty of mollusc shells, is the best example of a natural armor material that exhibits structural robustness, despite the brittle nature of their ceramic constituents. This material consists of about 95% inorganic aragonite with only a few percent of organic biopolymer by volume. New research at the university of South Carolina reveals the toughening secrets in nacre: rotation & deformation of aragonite nanograins absorb energy in the deformation of nacre. The aragonite nanograins in nacre are not brittle but deformable. The new findings may lead to the development of ultra-tough nanocomposites, for example for armor material, by realizing the rotation mechanism.

Super-tough and ultra-high temperature resistant materials are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Structural ceramics have largely failed to fulfill their promise of revolutionizing engines with strong materials that withstand very high temperature. The major problem with the use of ceramics as structural materials is their brittleness. Although many attempts have been made to increase their toughness, including incorporation of fibers, whiskers, or particles, and ZrO2 phase transformation toughening, currently available ceramics and their composites are still not as tough as metals and polymers. The brittleness of ceramic materials has not yet been overcome. It has proven difficult to solve this problem by conventional approaches.

On the other hand, Nature has evolved complex bottom-up methods for fabricating ordered nanostructured materials that often have extraordinary mechanical strength and toughness. One of the best examples is nacre. It has evolved through millions of years to a level of optimization not currently achieved in engineered composites.

This material has a brick-and-mortar-like structure with highly organized polygonal aragonite platelets of a thickness ranging from 200 to 500 nm and an edge length about 5 µm sandwiched with a 5-20 nm thick organic biopolymer interlayer, which assembles the aragonite platelets together. The combination of the soft organic biopolymer and the hard inorganic calcium carbonate produces a lamellar composite with a 2-fold increase in strength and a 1000-fold increase in toughness over its constituent materials.

Such remarkable properties have motivated many researchers to synthesize biomimetic nanocomposites that attempt to reproduce nature’s achievements and to understand the toughening and deformation mechanisms of natural nanocomposite materials.

Dr. Xiaodong Li, who heads the Nanostructures and Reliability Laboratory at the University of South Carolina, and his team have published papers that examine the role of nanostructures in the brilliant properties of nacre. In a first paper (" Nanoscale Structural and Mechanical Characterization of a Natural Nanocomposite Material: The Shell of Red Abalone"), the group reported the discovery of nanosized grains (particles) in nacre. However, the functionality of these aragonite nanograins was entirely unknown. Subsequently, lots of research groups asked: What roles do the nanoscale structures play in the inelasticity and toughening of nacre? Can they learn from this to produce nacre-like nanocomposites?

In a recent follow-up paper, Li and his group now reveal the functionality of these aragonite nanograins. The paper is titled "In Situ Observation of Nanograin Rotation and Deformation in Nacre", which appeared in the September 14, 2006 online edition of Nano Letters.

"To reveal the secret recipe of nacre is not an simple job" Li explains his research to Nanowerk. "We developed a micro-mechanical tester that can be used inside an atomic force microscope. They performed tensile and bending tests on nacre in situ where the nacre surface was imaged simultaneously by the atomic force microscope. The discoveries - rotation and deformation of aragonite nanograins clarify the earlier misunderstandings in modeling work, and provide a nanoscale modeling boundary condition. This opens up opportunities to create nacre-like ultra hard materials."

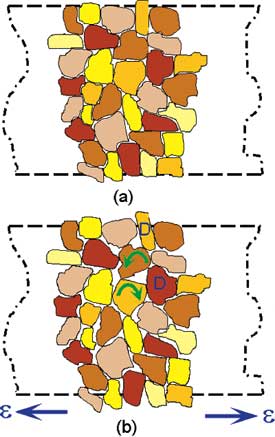

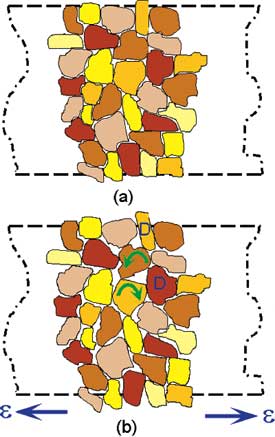

The grain rotation and deformation mechanisms in nacre aragonite platelets can be summarized by this figure:

On tension, the biopolymer between the nanograins is stretched in the tensile direction, which allows space for definite grains to rotate. Since the shape of these nanograins is normally irregular, the rotation of individual nanograins will push their neighbor grains apart, thereby leading to an increase in the spacing between the rotated nanograins and their neighbor grains (as shown in b).

With no outside applied strain/stress, nanograins with irregular shapes are originally packed closely by the biopolymer adhesives to form a sturdy structure (as shown in a).

The spacing behavior between the nanograins within an aragonite platelet causes the aragonite platelet to expand in the direction perpendicular to that of the applied strain/stress.

Schematics of grain rotation and deformation mechanisms in an aragonite platelet. D denotes grain deformation. The blue arrows denote the tensile direction. Green arrows denote the rotation direction of grains.(Reprinted with permission from the American Chemical Society)

The new findings are expected to revolutionize the way of preparing hard ceramic materials and structural parts, and will open up new application opportunities of ceramic materials and other materials as well.

Li points out that Nature has long been using bottom-up nanofabrication methods to form self-assembled nanomaterials that are much stronger and tougher than lots of manmade materials formed top-down.

"Mother Nature knows best" Li says. "Nature has evolved highly complex and elegant mechanisms for materials design and synthesis. Living organisms produce materials with physical properties that still surpass those of analogous synthetic materials with similar phase composition. They must turn our attention to Nature's designs and fabrication of materials. There is still a lot they must learn from Nature."

Super-tough and ultra-high temperature resistant materials are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, aircrafts, and spacecrafts. Structural ceramics have largely failed to fulfill their promise of revolutionizing engines with strong materials that withstand very high temperature. The major problem with the use of ceramics as structural materials is their brittleness. Although many attempts have been made to increase their toughness, including incorporation of fibers, whiskers, or particles, and ZrO2 phase transformation toughening, currently available ceramics and their composites are still not as tough as metals and polymers. The brittleness of ceramic materials has not yet been overcome. It has proven difficult to solve this problem by conventional approaches.

On the other hand, Nature has evolved complex bottom-up methods for fabricating ordered nanostructured materials that often have extraordinary mechanical strength and toughness. One of the best examples is nacre. It has evolved through millions of years to a level of optimization not currently achieved in engineered composites.

This material has a brick-and-mortar-like structure with highly organized polygonal aragonite platelets of a thickness ranging from 200 to 500 nm and an edge length about 5 µm sandwiched with a 5-20 nm thick organic biopolymer interlayer, which assembles the aragonite platelets together. The combination of the soft organic biopolymer and the hard inorganic calcium carbonate produces a lamellar composite with a 2-fold increase in strength and a 1000-fold increase in toughness over its constituent materials.

Such remarkable properties have motivated many researchers to synthesize biomimetic nanocomposites that attempt to reproduce nature’s achievements and to understand the toughening and deformation mechanisms of natural nanocomposite materials.

Dr. Xiaodong Li, who heads the Nanostructures and Reliability Laboratory at the University of South Carolina, and his team have published papers that examine the role of nanostructures in the brilliant properties of nacre. In a first paper (" Nanoscale Structural and Mechanical Characterization of a Natural Nanocomposite Material: The Shell of Red Abalone"), the group reported the discovery of nanosized grains (particles) in nacre. However, the functionality of these aragonite nanograins was entirely unknown. Subsequently, lots of research groups asked: What roles do the nanoscale structures play in the inelasticity and toughening of nacre? Can they learn from this to produce nacre-like nanocomposites?

In a recent follow-up paper, Li and his group now reveal the functionality of these aragonite nanograins. The paper is titled "In Situ Observation of Nanograin Rotation and Deformation in Nacre", which appeared in the September 14, 2006 online edition of Nano Letters.

"To reveal the secret recipe of nacre is not an simple job" Li explains his research to Nanowerk. "We developed a micro-mechanical tester that can be used inside an atomic force microscope. They performed tensile and bending tests on nacre in situ where the nacre surface was imaged simultaneously by the atomic force microscope. The discoveries - rotation and deformation of aragonite nanograins clarify the earlier misunderstandings in modeling work, and provide a nanoscale modeling boundary condition. This opens up opportunities to create nacre-like ultra hard materials."

The grain rotation and deformation mechanisms in nacre aragonite platelets can be summarized by this figure:

On tension, the biopolymer between the nanograins is stretched in the tensile direction, which allows space for definite grains to rotate. Since the shape of these nanograins is normally irregular, the rotation of individual nanograins will push their neighbor grains apart, thereby leading to an increase in the spacing between the rotated nanograins and their neighbor grains (as shown in b).

With no outside applied strain/stress, nanograins with irregular shapes are originally packed closely by the biopolymer adhesives to form a sturdy structure (as shown in a).

The spacing behavior between the nanograins within an aragonite platelet causes the aragonite platelet to expand in the direction perpendicular to that of the applied strain/stress.

Schematics of grain rotation and deformation mechanisms in an aragonite platelet. D denotes grain deformation. The blue arrows denote the tensile direction. Green arrows denote the rotation direction of grains.(Reprinted with permission from the American Chemical Society)

The new findings are expected to revolutionize the way of preparing hard ceramic materials and structural parts, and will open up new application opportunities of ceramic materials and other materials as well.

Li points out that Nature has long been using bottom-up nanofabrication methods to form self-assembled nanomaterials that are much stronger and tougher than lots of manmade materials formed top-down.

"Mother Nature knows best" Li says. "Nature has evolved highly complex and elegant mechanisms for materials design and synthesis. Living organisms produce materials with physical properties that still surpass those of analogous synthetic materials with similar phase composition. They must turn our attention to Nature's designs and fabrication of materials. There is still a lot they must learn from Nature."

No comments:

Post a Comment